Operating in a new industrial zone with 67,000 square meter land and 32,000 square meter building area we have over 200 equipments to make various types of fasteners.

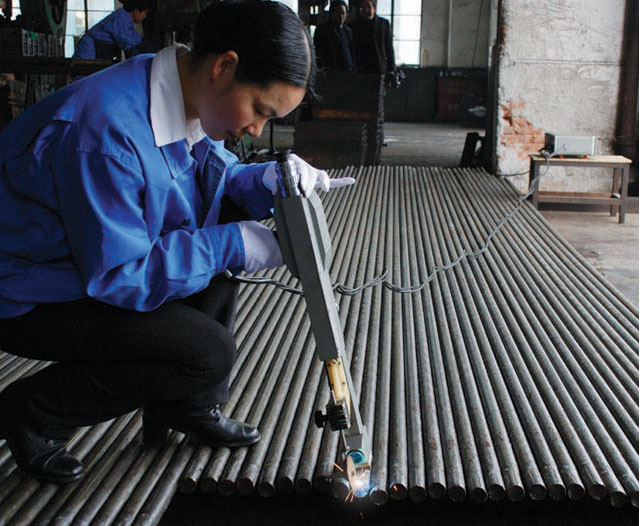

Quality assurance begins at incoming material inspection. In addition to the chemical composition analysis we use Spectrum Detection Technology to test material rod by rod.

Coreless grinding to assure surface accuracy and remove any possible cracks.

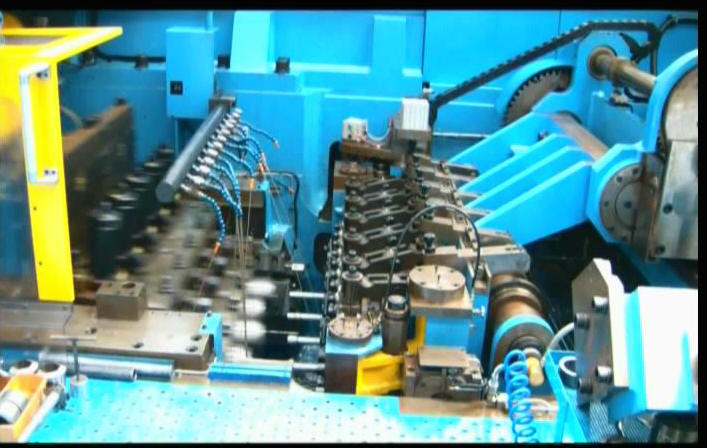

Multi-station cold forging head machine for bolts up to M36 or 1.5" of length 350mm. It is the largest cold heading machine in Asia.

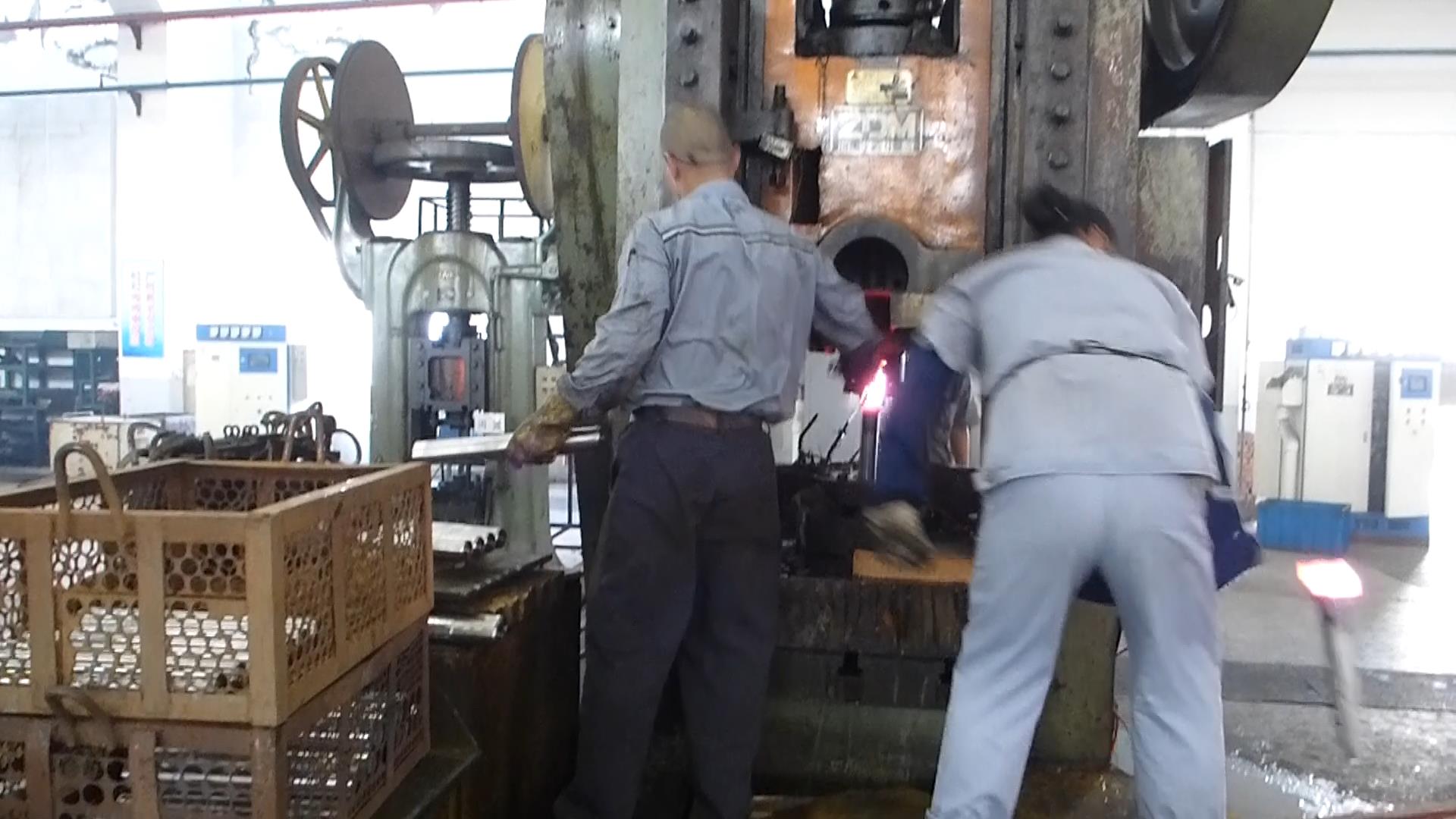

Hot forging head machine with temperature control to avoid over burning with diameter up to 36mm or 1.5" and length up to 450mm.

Six heat treatment lines to meet different requirements of various hardness and diameters.

Quenching and Tempering are under accurate temperature control and finished in one process.

Two Dacromet coating lines.

Various auto cold heading machines.